Nordson introduces new high-speed modular jet valve that micro-deposits adhesives

Micro-depositing adhesives at a speed of 1000Hz

A recently launched modular jet valve is designed for dispensing precise and repeatable micro-deposits of sealants, adhesives and other liquids at high speed. The jet valve is said to keep up a continuous speed of 1000Hz and allow bursts up to 1500Hz.

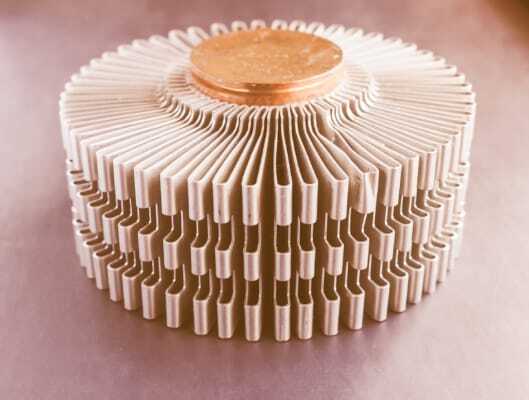

Tiny adhesive deposits on any surface with modular jet valve

According to Nordson, their PICO Pulse is capable of delivering micro-deposits as tiny as 0.5nL. The jet valve is suitable for any surface and even performs in the most demanding areas such as substrates that are hard to reach or uneven. The precise dispensing results from variable stroke control. Changes in the production design are accomplished through the modular design of the jet valve.

Reduced downtime with the new jet valve

The valve´s modular design and latch-free mechanism enables fast servicing of the valve resulting in less downtime. Nordson reports also that downtime was shortened when replacing wetted parts which come into contact with medium under pressure. The jet valve can be used to dispense a broad selection of assembly fluids with different properties such as viscosity and movement of flow.

How it works

See below how jet dispensing compares to more conventional contact dispensing when applying adhesives and sealants.

What solution are you looking for?

We are specialized in the nordson introduces new high speed modular jet valve that micro deposits adhesives. Need the best products or advice? Then please leave your details and we will get in touch.