New fast curing adhesive disrupts various markets

New fast curing adhesive challenges trusted systems

The adhesive market has recently been shaken by the entry of a new fast curing adhesive which challenges trusted bonding solutions such as epoxy and polyurethane. What makes this new adhesive revolutionary is its extremely reactive nature which allows curing within 2 seconds at its fastest. This fast curing glue is versatile and can be applied manually, integrated into an automatic application system or even injected into lightweight materials

The rapid cure adhesive has properties beyond short curing time

Not only is the new rapid cure adhesive unprecedentedly fast drying but it also provides bonds of sufficient strength while only a small amount of glue is applied. The adhesive is also very light compared to other structural adhesives. Additionally, properties such as wide operating temperature range, elasticity and curing at room temperature bring along long term benefits for various industries. Cost reduction, increased process efficiency and reduced carbon footprint are goals the strong, fast drying glue can help to reach.

From local reinforcement to structural fastener bonding with fast curing glue

As the fast curing adhesive is new to the market, new opportunities and applications emerge frequently. Currently, the adhesive is used in the automotive industry and furniture making. Additionally, its suitability to aerospace applications has been confirmed.

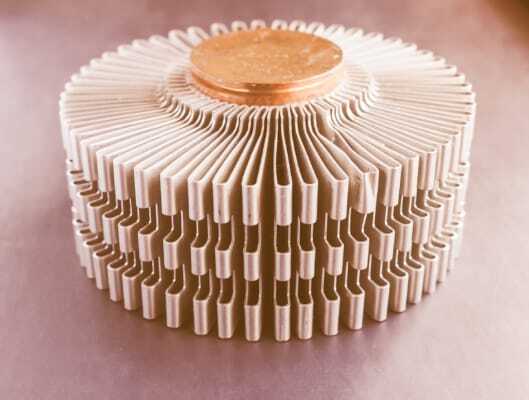

Structural bonding of fasteners, reinforcing lightweight materials (such as honeycomb and sandwich materials) and bonding different composite materials are all applications the new fast curing glue is made for in vehicle assembly. On the other hand, the fast drying adhesive can be used to create anchors and local reinforcements for wood based panels. This makes the adhesive ideal for producing lightweight, sustainable furniture.

The future of the fast curing adhesive seems bright. It provides durable solutions at lower costs than alternative adhesives and leaves room for innovative applications. All thanks to one chemistry - polyurea.

What solution are you looking for?

We are specialized in the new super fast curing adhesive disrupts various markets. Need the best products or advice? Then please leave your details and we will get in touch.