Mattress adhesive and application methods

The need for mattress adhesive is greater than ever

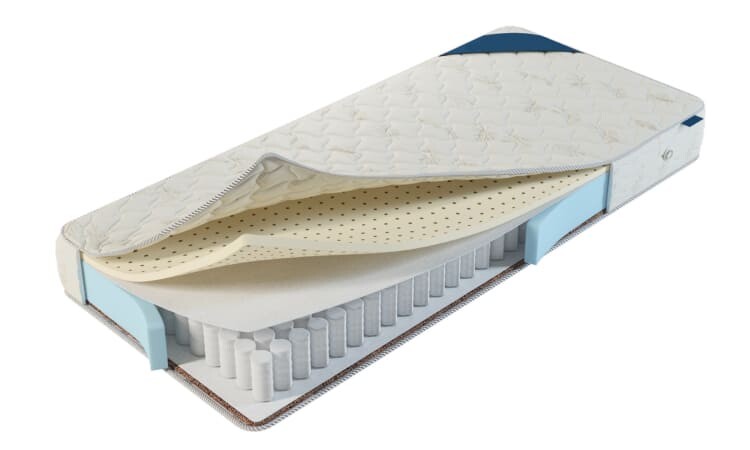

Mattress adhesive plays an important role in the mattress and bed making industry. The glue is responsible for keeping the different layers of mattresses together by bonding materials that are under the cover. Mattress adhesive can be used for instance for toppers, pocket spring and sandwich mattresses as well as open and closed cell foam mattresses, 7 zone mattresses and gel and memory foam mattresses.

The mattress and bed making industry is currently experiencing changes in regards of materials and material quality: more and more foams are used to make mattresses, and the need for efficient solutions is becoming paramount. Therefore, the mattress adhesives market is shifting towards more sustainable solutions such as hot melt glues and advanced water based adhesives. At the same time the requirements and need for mattress glue are greater than ever: the finished products must be long lasting, well ventilated, efficient to pack and transport as well as easy to clean and store without compensation on the quality.

Here you will find the different types of adhesives for mattresses, their advantages and disadvantages as well as application methods that make the process superior.

The right mattress glue boosts efficiency

Mattress adhesive brings along great advantages, not only due to its properties, but also the variety of possible application methods and equipment that can be customized to become an integral part of the production process. Once the adhesive application is integrated into the process, the overall efficiency improves regarding both cost and time in production, packaging, storing and transport.

The mattress adhesive application methods include rolling, spraying and beads. All these methods can be realized manually, semi automatically or automatically. For all these application methods to be optimal, proper implementation and training are required. Manufacturers of mattress adhesives provide products, suitable equipment and training to guarantee you the most efficiency.

New technologies allow for more and more efficient systems:

- Plug-and-play easy spray systems: an application process can be given a boost by using an easy to use spray system. These are often fully mobile and can be used in any location as long as compressed air connection is available. All you need to do is plug in the system and start spraying the mattress glue. Beds are ready remarkably faster when this method is used.

- Zero overspray systems: the development in transfer efficiency has resulted in zero overspray systems which represent 100% transfer efficiency. This means that all the adhesives for mattresses applied will be used, and none will be lost. These systems are enabled by the right combination of mattress adhesive and the right advanced application method.

- Immediately curing products: water based mattress adhesive systems that cure immediately, through forced curing process, remarkably improve process efficiency. The zero curing time allows for an uninterrupted flow of adhesive application, product processing and packaging. This allows for improved cost and time efficiency as well as controlled processes throughout the production without compromising to quality. This not only improves the mattress assembly process but thanks to this glue beds are generally produced faster.

The 3 types of adhesives for mattresses

Mattress adhesive is used in bonding foams, pocket coil assemblies, fabrics and fibers. It is crucial that the mattress glue is non-yellowing, durable, flexible as well as easy and fast to apply so that it does not affect the looks of the mattress, allows for transport and storing, and optimizes processes while resulting in long lasting products. The wished result can be achieved by one of three mattress adhesive systems which bond for example cotton, coconut fiber, foams and non woven materials.

1. Solvent based mattress glue solutions

The most traditional form of mattress adhesives are solvent based systems. These systems provide strong bonds, generally stronger than water based mattress glues. They can be applied by roll coating, spray or beads and dots.

The disadvantage of solvent born mattress adhesives is that they tend to release solvent fumes and adhesive residue in the air as they set when the solvent evaporates. Nevertheless, the new technologies allow for more user friendly systems where the share of solid parts is higher. This results in less solvent in the product as well as reduces the amount of product needed to complete the application.

2. Waterborne mattress adhesives

Water based adhesives are a step towards more sustainable bonding in the mattress industry. They do not form as strong bonds as their solvent based alternatives, but that is no problem, for a mattress adhesive does not necessarily need to be strong, as long as it is, and remains, flexible and odorless. Also these systems are applicable by spray, beads and dots as well as roll coating.

The great advantage of waterborne mattress adhesive is that it is environmentally friendly, releasing only water while setting by evaporation. The evaporation process, however, generally takes longer than when working with solvent containing products. If the longer setting time is not taken into consideration, the water may remain in the mattress and encourage mold forming once packed in plastic. Fortunately, the development of adhesive technology makes it possible to let the water based mattress adhesives cure faster and minimize overspray.

3. Hot melt mattress adhesive

The newest, and most efficient mattress adhesive on the market is hot melt which is applied with hot air and sets as the heat dissipates. Hot melt is the mattress glue with the fastest curing process and least risks as it involves neither solvents nor water thanks to its 100% solid consistency.

Hot melt glues have rapid initial tack which allows for more efficient processes and requires less mattress adhesives. The only downside of mattresses that use hot melt, is that they may make a cracking noise when the adhesive is dry. However, the continuous development and innovation are removing this disadvantage.

Hot melt adhesives for mattresses are usually applied as spray regardless whether they are a one or two component systems. There are also rollable formulations of hot melt mattress adhesives made possible by reducing the solid share to about 75%.

Standards and certificates for mattress adhesives

As durability, comfort and safety are key factors in mattress production and the finished products, many mattress adhesives are certified according to standards set by national and international standardization bodies. Below you can find examples of certificates relevant to mattress glues. These are recognized throughout the bed industry.

- TÜV Rheinland provides inspection services, testing and certifying to assess products and manufacturing processes regarding safety and sustainability.

- Eco Passport can be achieved for textiles when two stages of testing are done. The Stage I Eco Passport tests are run according to OEKO-TEX® Restricted Substances List and Manufacturing Restricted Substances List. Stage II includes analytical verification of products in OEKO-TEX® laboratories. The Eco Passport means that the mattress adhesive is suitable for use in sustainable production of human ecologically optimized textiles.

- GB18583-2008 is the Chinese standard for Indoor Decorating and Refurbishing Materials - Limit of Harmful Substances of Adhesives. Testing according to the Chinese standard is especially relevant for products that are targeted to the Asian market.

- GREENGUARD Gold Certified ® offers criteria for safety factors, rather strict by nature. The factors assess the product´s safety regarding sensitive individuals such as children and elderly. The certification also insures that the products are safe to use in environments such as schools and healthcare establishments. It is referenced by both The Collaborative for High Performance Schools (CHPS) and the Leadership in Energy and Environmental Design (LEED) Building Rating System.

Find the right adhesives for mattresses and improve efficiency

If you are in need of a durable and efficient adhesives for mattresses, do not hesitate to contact us. Your enquiry with us will end up to our mattress adhesive specialists who are happy to assist you in finding the right system and application method as well as making mattress adhesives application an integral part of your production process. Get in touch, and maximize efficiency.

What solution are you looking for?

We are specialized in the furniture and home. Need the best products or advice? Then please leave your details and we will get in touch.