Furniture adhesive

Furniture adhesive for safety and sustainability

The furniture industry makes use of a great deal of adhesives which improve the production process and guarantee safety and suitability of the finished products. Furniture adhesive systems are used for creating bonds between fabrics, foams, wood, metals and plastics. As the variety of adhesives and application within the furniture industry is wide, this article focuses on adhesives used for bonding soft furniture and furniture upholstery including furniture for schools, hospitals, offices and airports as well as seats in vehicles such as trains and airplanes.

Beneficial properties of furniture adhesives

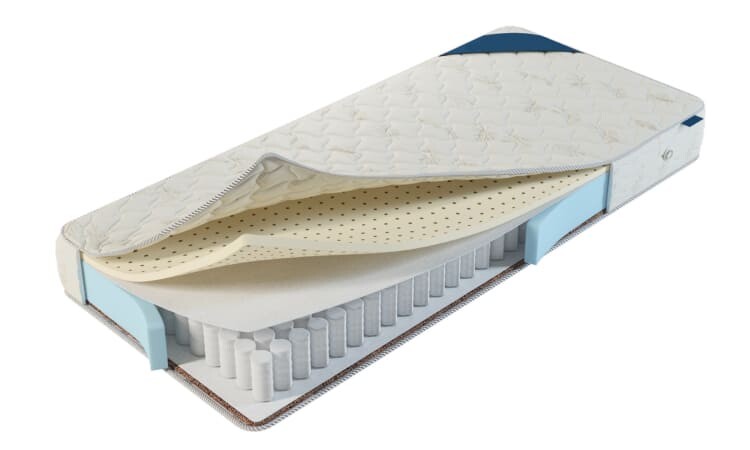

In soft furniture and furniture upholstery the task of the adhesive is to keep the furniture foam in place much like in the mattress industry. During the application it is crucial that the furniture glues do not penetrate the pores of the substrate but rather remain on the surface enabling strong bonds with other materials without affecting the properties of the substrates. Additionally the adhesive must be able to absorb great tension right after being applied. Most importantly, the right adhesive can improves overall efficiency by being fast and easy to apply.

Next to the properties required during the application, there are a number of characteristics a furniture adhesive should have, in order to support the quality of the finished products. These include:

- Elasticity: as upholstery and soft furniture involve adhesives for soft and flexible surfaces, also the adhesive must remain elastic and not break due to movement of the material.

- Invisibility / non-yellowing: the purpose of furniture adhesives is to bond materials together unnoticeably. Therefore, it is crucial that the systems retain their original color and do not turn yellow when the bonds get older.

- Eco-friendliness: in the furniture manufacturing, sustainability is becoming more and more important. Therefore, also the products used during the process must contribute to reduced risk of environmental contamination.

- Chemical resistance: furniture used in public areas, institutions and vehicles should be resistant to chemicals so that even intensive cleaning and aggressive substances do not affect them. Therefore, the adhesives must not be affected either.

- Durability: the most important reason to use furniture glues is the durability and long life span they give to the products.

Bonding for furniture upholstery and soft furniture

Traditionally the furniture industry made use of solvent based strong adhesives. However, for decades the trend has been towards environmentally and user friendly products. Therefore, the most used furniture adhesives nowadays are either water based dispersion adhesives or hot melt glues.

- Waterborne dispersion adhesives: water based adhesives for furniture industry are environmentally friendly and solvent free. They cure by evaporation as the water in them leaves the system. The curing process can also be forced, which results in immediate curing saving time and making the process more controllable. They can be applied by spray, roll coating or beads and dots. Spray applications are by far the most common.

- Hot melt furniture adhesives: hot melt glues are thermoplastics which are applied without using water or solvents. These systems are applied using heat and they cure as they cool down. Solvent free hot melt systems for furniture are applied predominantly by spray.

Note that some adhesives can be given additional properties or the existing ones can be enhanced by modifying the product with a solvent based solutions. These solutions can for instance make the bond stronger, increase the adhesive´s heat resistance and enhance the extent of water resistance of polyurethane adhesives. The possibilities to modify the furniture bonding solutions are becoming more and more important, since the demand for furniture is growing.

Certification of furniture glues products

Sustainability and safety as well as suitability for specific applications are of high importance for furniture and furniture adhesives. Along with these factors come the relevant certificates. Below you can find some examples of certificates that benefit furniture adhesives.

- Eco Passport can be achieved for textiles in the furniture market. It guarantees that no OEKO-TEX® restricted substances are used in the products or manufacturing, and they are suitable for use in sustainable production of human ecologically optimized textiles.

- TÜV Rheinland provides inspection services, testing and certifying to assess products and manufacturing processes regarding safety and sustainability.

- GREENGUARD Gold Certified ® offers strict criteria for safety factors that assess the product´s safety regarding sensitive individuals such as children and elderly. The certification insures that the furnitures is safe to use in environments such as schools and healthcare facilities.

- GB18583-2008 is the Chinese standard for Indoor Decorating and Refurbishing Materials - Limit of Harmful Substances of Adhesives. This standard is especially relevant for furniture adhesives used in goods targeted at the Asian market.

Assistance & advice for finding the ideal furniture adhesive

Finding the right adhesive for furniture upholstery and soft furniture may be challenging due to the different types of foam materials that require bonding, and the complete production processes that should be made as efficient as possible. In case you require any additional information, advice on products or application, or training in furniture adhesives, do not hesitate to contact us. Our specialists are here to help you out!

What solution are you looking for?

We are specialized in the furniture and home. Need the best products or advice? Then please leave your details and we will get in touch.